Core drilling is one of the most important aspects in the construction field and a precise concrete cutting technique. This type of drilling allows you to cut holes into concrete, paved surfaces, and brick. This precise technique is used for those preparing pipes and cables, but also ducting for HVAC purposes. Because this type of drilling is special, you need to know the basics and the safety needed to have successful drilling when the time comes.

Basics of Core Drilling:

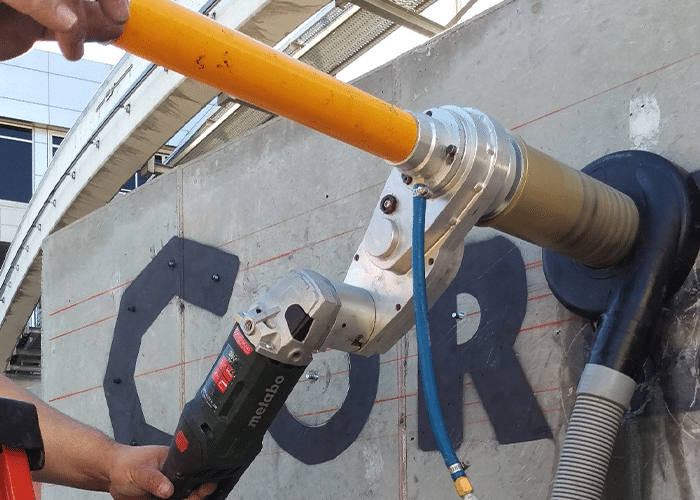

To get started on your core drilling, you need a coring tool (core drill). With the purpose of cutting large holes, this type of drill is able to cut through most desired surfaces. Cement, tile, concrete, and sandstone are just a few of the surfaces this powerful and useful tool can cut through. The main element is the core drill bit, also known as the annular cutter. This bit is a cylinder element that is hollow, usually with an abrasive surface.

How it Works:

When the mounted teeth are attached to the surface you are cutting, the rotation of the core drill bit starts to make a slow circle shaped hole. It should be noted that the diameter and the size of the bit determines how far it can go until it is full of the core materials, which are the cylindrical pieces of uncut materials. Once this is full, the drill isn’t able to go any further in the process. Extract all the core materials from the surface you are working on which creates the cylindrical hole. Do this drilling and extracting process until you have cut the hole of your desired length on the surface you are cutting.

Preparation Before Drilling:

Before any drilling can happen, you need to make sure there are not any pipes, cables, or other utilities under the surface you were planning on cutting. Once this is done, measure the thickness of the wall so you know ahead of time how deep you need to cut. This will save you a tremendous amount of time if you’re able to drill through the wall in a single pass.

Once you have done these steps, it is time to configure the drill. You need to make sure you have selected the correct drill bit with the right length for the surface you’re about to cut. If you are using a power drill, you need to attach the core bit to the arbor and then the arbor-bit second. With these two in place, then you can attach the guide drill bit. Make sure your drill is on the desired setting for the surface and type of hole you are trying to make and start drilling!

Safety With Core Drills:

Because this technique takes a lot of precision and is heavy-duty, safety is always the main focus. As you probably already know, eye goggles are a must to make sure dust and debris do not get in your eyes. Make sure your shoes are non-slip as well. Slipping when using this drilling technique can cause you to have uneven holes. Core drilling can be loud at times so ear plugs are also recommended for this type of job. Investing in the right tools will make this job more safe and easier on you as well. Getting the right high-quality drill and bits for your project will allow for less possibilities of issues with your cutting and your safety.

U.S. Saws is an innovator in the tool industry. Core drilling is a popular technique in this industry because of the many different surfaces you can use it for. Knowing how to use it and having the right materials take your project to the next level. As there are many factors to consider in choosing your next core drilling project, engaging with a company to help guide you will ensure your project is completed promptly in the right manner. Contact U.S. Saws today to find all of your core drilling needs!