Dust and debris are normal outcomes when cutting, polishing, and grinding during a project. Because of the abundance of dust, it can become time-consuming and difficult at times to clean it all up. You can use sweeping and dry brushing, but taking another hour to clean up is the last thing you want to do after a long day working on a project. If you want to save time and money, concrete vacuums are your number one choice. Normal vacuums you use around the house aren’t strong enough to handle concrete debris; you need a high-quality industrial vacuum. These are one of the most important tools in the construction business not just because it makes the job easier, but for worker safety as well.

Why Are They Important?

The saying “work smarter, not harder” comes into full effect when it comes to using concrete vacuums. You can spend an extra hour cleaning up alone after already spending eight hours on a tough project if you’re not using an industrial vacuum. These types of vacuums are great to clean up ultra-fine dust and powder after cutting. This is a crucial process because the dust particles can cause the floor you are working on to be slick without you even noticing. Debris and dust during a project causes it to be airborne as well. Without a concrete vacuum, this can cause these particles to get in your eyes and nose which can cause overwhelmingly health hazards.

Make Sure You Have the Right Vacuum:

Depending on the project you are working on, you need to make sure you have the right size to ensure safety and to make the project go as smooth as possible. There are four possible indicators that the vacuum you are using is too small:

1. You constantly have to empty it

2. There is dust still on the surface

3. When cutting, polishing, or grinding there is airborne dust

4. The filter is constantly clogged

Even though at times these vacuums can be pricy, it is worth spending more to ensure the safety of all workers present. Not only can improper vacuums cause damage to yourself, but to your tools as well. Grinding and cutting with layers of dust can damage your tools. The dust build up can lead to diamond tooling wear because of the abrasive nature of concrete dust. Having the right vacuum for the job will help you keep your tools working properly and save you money from having to spend money on new ones.

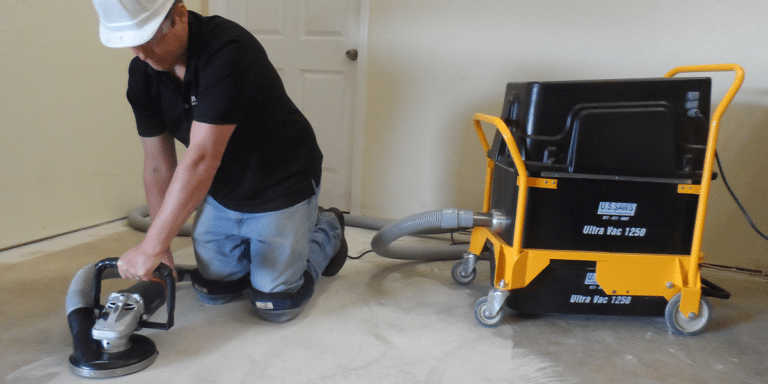

When looking for a concrete vacuum, make U.S Saws your number one choice. Our Ultra Vac 1250 Dust Collector is the perfect fit for any project. With its lightweight and durable foundation, this vacuum can handle any job small or large. Already have a vacuum but need parts? U.S. Saws has you covered! With adapters, hoses, and poly cams, we have what you need to make sure your vacuum is working efficiently and properly for your projects in the future.

U.S. Saws is an innovator in the tool industry. Concrete vacuums are a crucial tool that will take your project to the next level with safety and progression. As there are many factors to consider in choosing the proper vacuum for your project, engaging with a company to help guide you to the right vacuum will ensure your project is completed promptly in the right manner and as safe as possible. Contact U.S. Saws today to find the concrete vacuum that meets your specific needs.