Diamonds are one of the hardest substances on earth, and while they can be buffed and polished into brilliant gems that adorn the crowns of royalty and the necks of celebrities, they are also a very handy medium for tools. Scoring a 10 for hardness on the Moh’s scale, diamonds are renowned for their beauty and durability, and diamond blades are no different. While not made of the stunning gemstone found on the fingers of the wealthy, a diamond blade will certainly evoke that same sense of awe in the eyes of the construction worker when viewed in action. Diamond blades are efficient and cut with precision. Two essential characteristics for the measure twice / cut once crowd. But how do you know which diamond blade is the right blade for your project?

What Is a Diamond Blade?

Diamond saw blades are created from synthetic diamonds. These synthetic diamonds are broken into small pieces and attached as a grit to the saw blade. They work with tools to provide a superior grinding action to coincide with the cutting action of the saw blade in order to work quickly and efficiently through abrasive material like concrete. It is important to know that one size does not fit all when it comes to using diamond blades. Knowing the medium through which the blade will be cutting, the depth of the cut required, and the location of the project are crucial details that help determine which blade is right for your project.

Understanding The Medium and Its Hardness

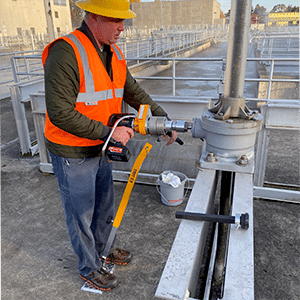

Diamond blades are efficient devices for cutting through a wide variety of mediums. Contractors commonly utilize these blades with a wide variety of saws, grinders, and core drillers, each requiring their own specific type of diamond blade based on the medium through which they intend to cut. Mediums ranking high on the Moh’s Scale require a slower shaft speed from the tool than mediums ranking lower on the scale, like concrete. Further, the medium decides the size and spacing of the teeth on the blade.

Concrete is a great example of a medium that benefits from the use of diamond blades due to its softer medium and highly abrasive nature. Because of this abrasive nature, cutting concrete is best used with diamond blades that require a faster shaft speed. When installing concrete, the cutting of control joints is critical in order to take control of concrete’s natural, and often times frustrating, habit of cracking. To cut control joints, the most efficient option is to utilize a walk behind saw with a diamond blade. This blade Early entry saws are another standard saw used during the installation process of concrete that highly benefits from the addition of a diamond saw blade. Handheld cut off saws may be used create decorative designs in freshly cured concrete. again, since this is concrete, diamond saw blades are handy due to their ability to make easy work of concrete yet in a precise manner. Diamond saw blades are not only necessary for concrete flooring work, but also for use with wall saws. Because these saws are cutting concrete, the teeth on the saw blade should have wide slots, like the U.S. Saws Supreme Concrete Blade.

When working with glass or glazed tile, it is important to utilize a diamond blade that will provide a smooth cutting action. Therefore, a blade with closely spaced segments is ideal in this situation.

Blade Size and Mesh

Another factor instrumental in ensuring your project is completed properly with a diamond blade it is ensuring you have the right size blade with the proper mesh to create those precision cuts. The mesh of a diamond blade determines the coarseness of the blade. A coarse mesh size of 20 to 60 is what would be used for concrete or masonry. Medium mesh size it’s ideal for glass and porcelain, while a fine mesh size is optimum for grinding and polishing.

The size of the blade is dependent on the job you’re trying to complete. for decorative work on concrete, a smaller blade makes the most sense. Should the job requires the cutting of control joints with a walk behind saw, then a larger blade will make faster work of the concrete. It is important for the longevity of the blade to ensure that you are using the right size blade for your project.

Wet Blades vs. Dry Blades

When shopping for your perfect diamond blade, you will see options for wet blades and dry blades. In order to choose the proper what or dry blade, it is vital to understand not only the medium with which you are working but also the location of that medium. Dust is a dangerous factor when cutting concrete and other mediums. one way to reduce the amount of dust emitted during the cutting process is by wet cutting. Wet saw blades are efficient at reducing friction that may occur during the cutting process. By reducing friction, the longevity of your blade will increase and ensure precision cutting for a longer period of time. Wet cutting is perfect for outdoor spaces as the blade requires constant application of water as the saw does its job.

Dry cutting is optimal for indoor spaces as it makes less of a mess with the water. However, while there is less water mass, dry cutting does increase the amount of dust released into the air. Therefore, it is imperative that safety measures are taken to prevent the inhalation of the silica dust created by dry cutting. It is recommended that dry cutting be used for shallow cuts as it requires airflow to reduce heat, as opposed to wet cuts which use water to reduce heat.

Also, keep in mind that dry cutting diamond blades may also be used wet. However, wet cutting specific diamond blades may never be used dry, as they are prone to overheating which may affect the outcome of your final product and damage a beautiful blade.

U.S. Saws is an innovator in the tool industry. Diamond blades are versatile saw blades that will take your project to the next level. As there are many factors to consider in choosing the proper blade for your project, engaging with a company to help guide you to the right blade will ensure your project is completed promptly in the right manner. Contact U.S. Saws today to find the Diamond blade to meet your specific needs.