When you enter a construction site and notice cracks and sunken areas, it can be stressful for everyone involved. Moisture problems, improper curing, and other outside influences can cause this to happen in most areas where concrete has been placed. If you are tasked with polishing concrete or maintenance, this previous damage can make the job more difficult and time-consuming.

If the floor is not thoroughly inspected, it can cause even more damage than is already there, especially if you cannot figure out what caused the cracks and sunken areas. There are numerous ways that concrete can be damaged, so it’s important to identify this damage early. Having the right knowledge and tools for such a task can help anyone perform the job at hand.

What Leads to Concrete Damage?

-

Improper Installation

When there is an abundant amount of moisture during the mixing and curing processes, this can be a main cause of improper concrete installation. This can be caused by the contractor being in a rush, or simply not being as qualified to do the job the correct way. Signs of incorrect installation can include spalling, blisters, and crazing which causes damage that needs to be fixed before you can continue with your main project.

-

Outdoor Elements

For concrete floors that are outdoors, these are going to be constantly affected by the elements we untimely can’t control at times. Natural causes such as wind, freeze-thaw occurrences, and rain can all cause damage to these concrete floors. The continuous freeze-thaw cycle that can occur slowly breaks down concrete, which causes the cracks you might see. Moisture is the primary cause for damage because its ability to freeze. The concrete expands and puts pressure on the material inside which the end result could cause major damage.

-

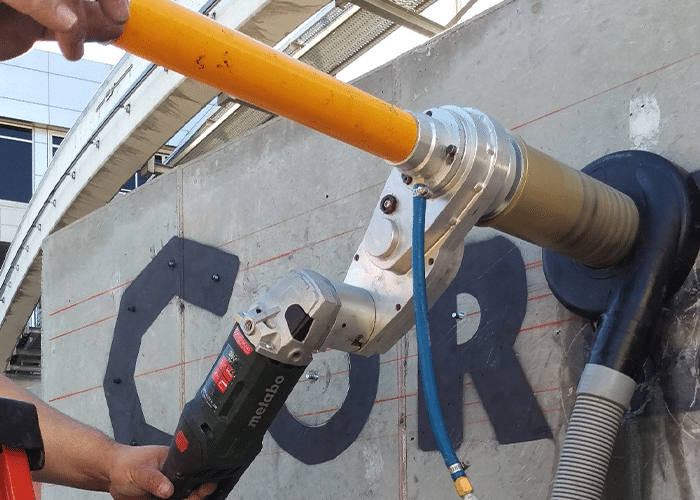

Corrosion

The biggest cause of concrete deterioration is corrosion. With the reinforced concrete floors, the steel bars that are inserted can become rusted. Even though most of the time the concrete offers its own layer of protection, chloride ions from salts can reach these bars through cracks in the concrete. Because this is a typical and reoccurring issue, having the concrete be maintained and installed correctly the first time is important.

How to Protect Your Concrete:

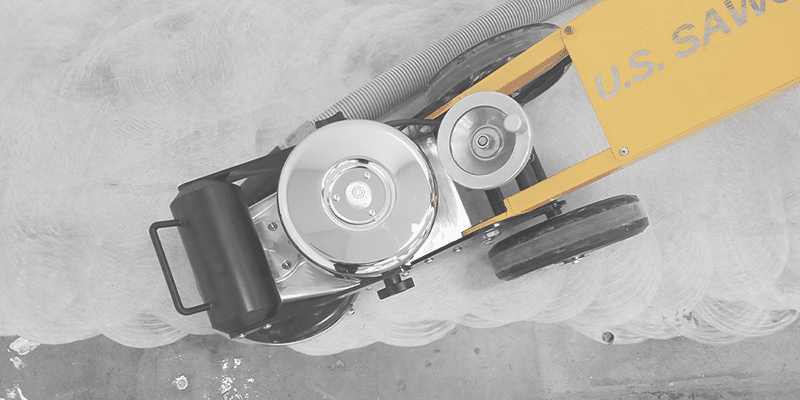

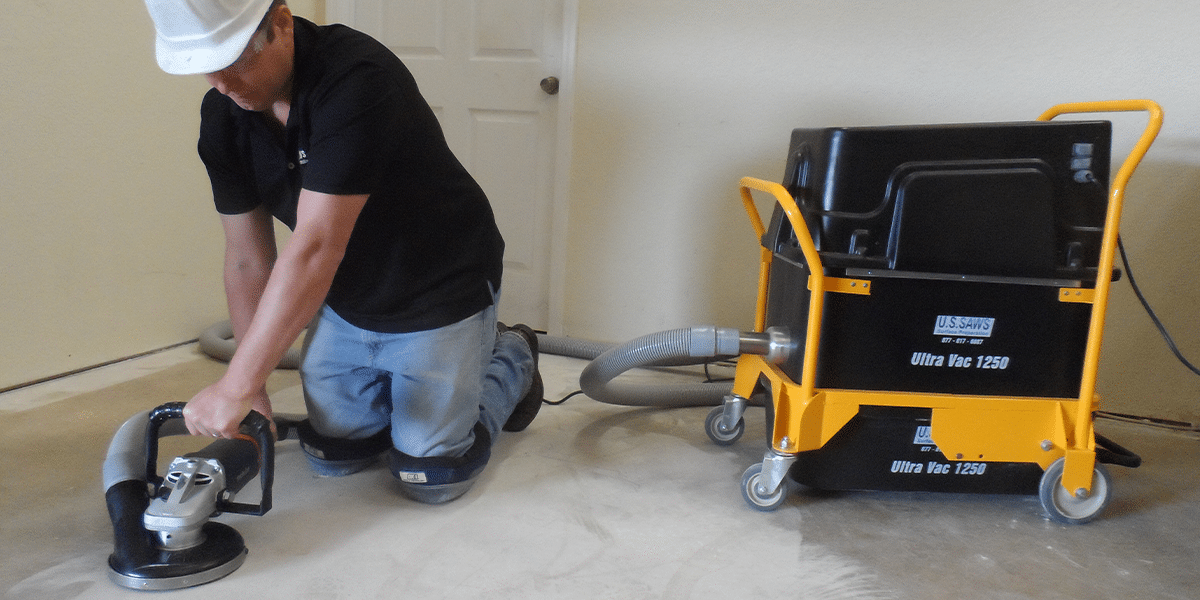

Although damage may be uncontrollable, proper maintenance can help prevent damage from getting worse over time. As mentioned earlier, proper installation can ensure that the concrete lasts, but a quality polish can also help prevent deterioration. Proper concrete grinding is a crucial step in making sure you have the most ideal concrete surface and getting rid of any unnecessary objects in the concrete. Before starting to work on the concrete, there should always be an inspection. If you find out about the quality and age of the floor, you will be able to better assess whether you need to fill only the cracks or replace everything completely

U.S. Saws is an innovator in the tool industry. Concrete requires the right knowledge and tools to get the job done the right way. Knowing what causes damages to these floors and how to maintain them is essential. As there are many factors to consider for your next concrete project, engaging with a company to help guide you will ensure your project is completed promptly in the right manner. Contact U.S. Saws today to find all of your concrete floor needs!